How to recognise artisanal pasta that is good for the health

In 2021 alone, 4 million tonnes of pasta were produced in Italy and found their way onto millions of tables in Italy and abroad.

But how much of this pasta is artisanal? And above all, how do we recognise the pasta which is good for our health?

The raw material: wheat

Grandpa Livio, the second owner of the pasta factory, taught us that to make good pasta “what counts is not so much the quantity, but the quality of the gluten” contained in the wheat grain.

It is therefore important to select durum wheat, preferably of ancient varieties, grown exclusively in Italy.

Furthermore, ideally, favouring quality means choosing wheat which has been organically farmed. To do this, the farmer carefully follows each step, applying cultivation techniques that first of all preserve the natural characteristics of the soil.

One example among the various farming methods applied is green manuring, or the sowing of plants capable of regenerating those substances that the soil needs to become fertile again.

If this care and attention is given, the wheat grain retains its properties, including today’s much-discussed protein: gluten, which will now be elastic and tough enough to make a truly nutritious pasta. (“is gluten bad for you?”)

Therefore, the organic raw materials we use are Capelli, Timilia (Sicilian wheat) and Emmer wheat (one of the oldest and most delicate flours used to make pasta), all of which are suitable for the production of a top-quality durum wheat flour.

Slow milling: the method of our trusted mills

Once the durum wheat has been selected, it is important to work it gently to obtain a flour of the highest quality.

In fact, during the milling phase, what happens?

The grain is exfoliated from its outer layer (bran) and is then gently processed so as not to damage the natural fibres, vitamins and minerals contained in it.

Hence, we work with mills that prefer to work slowly and steadily, without stressing the grains, so as to maintain low temperature during milling. As a result, the grain is not overheated and the flour obtained remains rich in substances that are good for our health.

Unfortunately, if the aim is to accomplish this process in a short time, the job is done very quickly at the expense of the nutritional value contained in the grain.

Low drying temperatures

After the flour reaches the pasta factory, we must continue to be the guardians of its hitherto preserved qualities.

Therefore, during the kneading and drying phase, it is important to maintain low temperatures because this is the only way, recognised by scientists, to limit possible thermal damage.

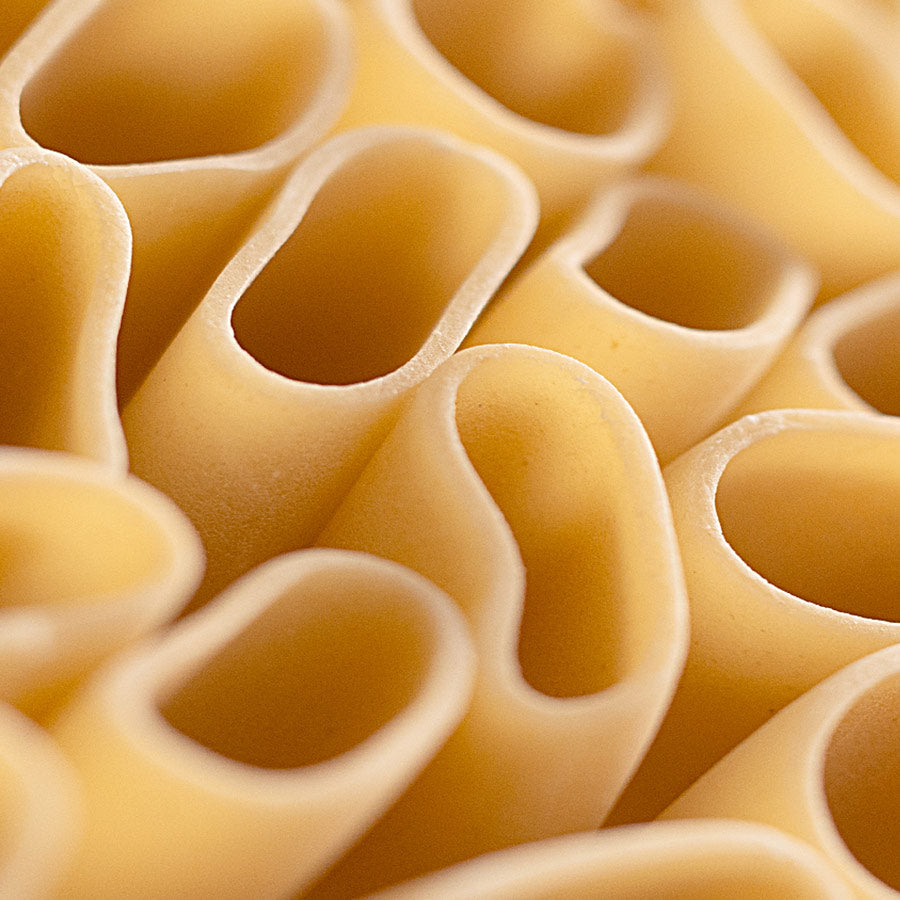

This care and attention results in our obtaining, on an aesthetic level, a creamy yellow pasta, as opposed to the orange-yellow of industrial production, and, on a nutritional level, a product containing an unaltered protein structure and which is therefore highly digestible.

In our pasta factory, we abide by what our grandparents taught us: pasta-making at temperatures that do not exceed 38°C, favouring slow and gentle processing. In fact, we achieve a drying time of 3 to 6 days (144 hours) before the pasta is packaged.

In conclusion, it is essential to take extreme care in every step: from the choice of wheat, to milling, drawing and drying. By always keeping temperatures low, the finished product can be obtained, without haste and a wholesome, highly digestible pasta can be enjoyed, with an extraordinary capacity to absorb sauces.