Pasta and the short supply chain: everything you need to know

Today more than ever we hear about short supply chains, zero-kilometre products, traceability: but what really lies behind these words?

The quality of pasta does not begin on the plate, but in the fields where the wheat grows, in the hands that mill it, and in those that transform the semolina into pasta. Understanding what a short supply chain is means discovering how each step – from field to table – can turn a simple food into a product of real value.

What is the short supply chain?

A short supply chain is a system where there are very few steps between the grower and the consumer.

It means transparency: knowing where the wheat comes from, who grew it, who milled it, and who turned it into pasta. It also means trust, because every step is traceable and identifiable.

Often, short supply chain is confused with the concept of zero-kilometre products, but they are not the same thing.

Zero-kilometre refers to geographical proximity: a product grown, processed, and sold in the same area. The short supply chain, instead, refers to the number of hands involved.

Thus, Timilia wheat grown in Sicily and processed in Tuscany is not zero-kilometre, but it remains a short supply chain if the path is direct, traceable, and transparent.

Not every short supply chain is synonymous with quality. In the technical sense, it simply means that there are few steps between field and table. But in its most virtuous meaning, a short supply chain also stands for respect for raw materials, transparency, and care at every stage of the process: from the wheat to the mill, to the pasta factory.

The short supply chain of pasta: what to look for?

The wheat

Everything starts with the choice of wheat.

Ancient varieties such as Cappelli or Timilia have retained their original characteristics, having undergone fewer genetic selections than modern varieties. In recent years, numerous international studies have shown that pasta made from these grains and dried slowly at low temperatures can bring health benefits, including better metabolic balance, lower cholesterol, blood sugar, and insulin levels, and greater digestive tolerance (read the article dedicated to scientific research).

The mill

In the mill, quality depends on the delicacy of the milling process. The wheat must be cleaned, selected, and ground without overheating, in order to preserve its nutritional properties. Semolina obtained at low temperatures keeps the aromas, colour, and natural characteristics of the grain intact.

The pasta factory

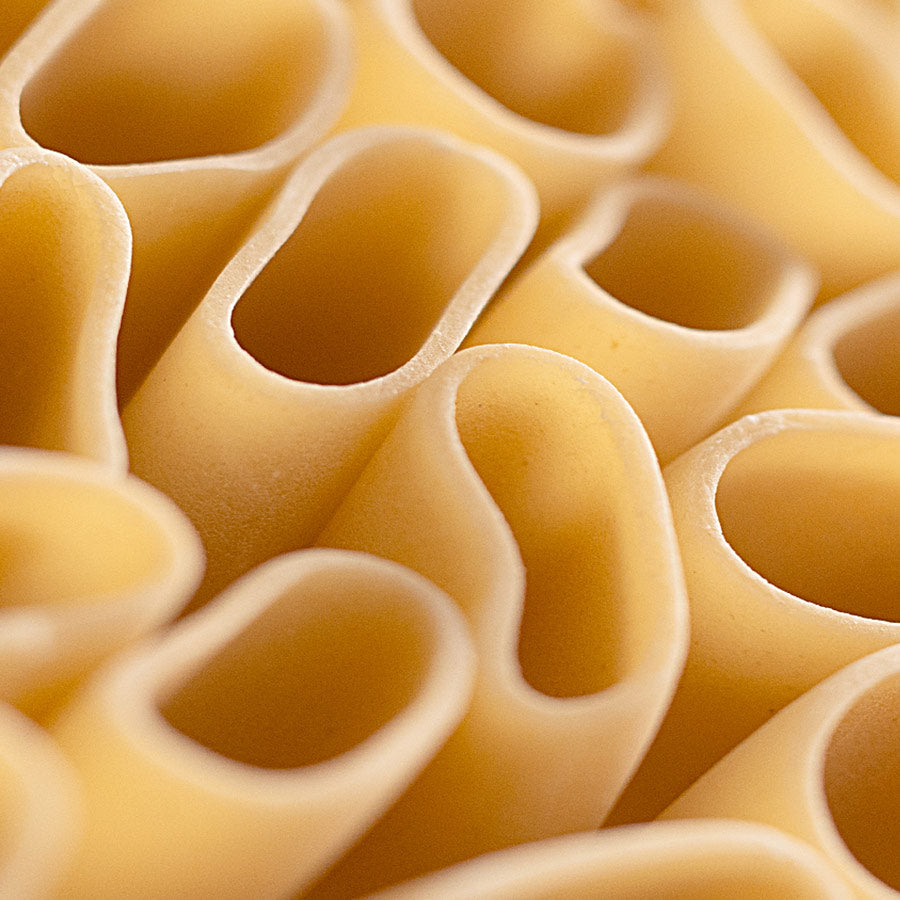

When the semolina reaches the pasta factory, skill and patience come into play. The slowness of drying – in our pasta factory it can take up to 6 days, depending on the shape – and strict temperature control – never above 38°C – safeguard the raw material and preserve the structure of gluten.

The result is a more balanced pasta: more digestible, with superior chewiness, better ability to hold sauce, and an authentic, full flavour.

How to recognise a short supply chain… on the label?

- Origin of the wheat

Always look for clear information about the origin of the wheat. The “EU” and/or “non-EU” labels often found on packaging do not allow precise identification. More detailed information (Italy, or even the specific region) gives a clearer picture of the supply chain.

- Place of milling

Since 2021, specifying the place of milling is no longer a legal requirement, but it remains a good transparency practice. Stating it helps the consumer to better understand the origin and path of the raw material up to processing.

- Production method

The indication “slow drying” alone is not enough. Some producers choose to state the actual drying time (in hours or days) and the maximum temperature used, a sign of special attention to processes and quality. These details – and not generic claims – tell the true story of commitment and quality.

- Clean ingredient list

True dry pasta is made only of durum wheat semolina and water. Two ingredients, nothing more: everything else is the result of time, care, and processing methods.

To learn more, click here.

A short supply chain is not a slogan, but a way of producing and thinking. It means knowing every step of the wheat’s journey, from the ear of grain to the package, and recognising the value of the hands that work it. A supply chain made of transparency, time, and respect, where few steps and much care become synonymous with quality.