Pasta Drying Temperature: Why Slow and Low Is the Best Choice

When it comes to pasta, quality is not only about the choice of wheat or the bronze-drawing method. There’s a crucial moment: drying. It’s during this phase that pasta develops its structure, flavor, and ability to hold up during cooking.

In this article, we explain why at Pastificio Fabbri we continue to dry our pasta slowly, at low temperatures — and why this process truly makes all the difference.

What is pasta drying?

Drying is the process that transforms fresh pasta into a dry product with a long shelf life by gradually removing internal moisture.

There are different approaches: in high-yield industrial production, pasta is dried within a few hours at high temperatures, sometimes up to 115 °C.

In contrast, artisanal pasta makers like us choose the long route: low temperatures (in our case, we never go above 38°C) and long drying times, up to six days, depending on the format.

Why choose slow, low-temperature drying?

A slow and gradual drying process best preserves the natural structure of the dough. Working at low temperatures helps to:

-

maintain the integrity of the gluten network, promoting even cooking;

-

avoid excessive gelatinization of starches;

-

improve digestibility and the pasta’s ability to hold sauces;

-

preserve a richer flavor profile, with a fuller taste and an authentic wheat aroma.

Another important aspect is furosine, a molecule that forms at high temperatures as a byproduct of the Maillard reaction. It is considered an indicator of heat stress and nutritional loss, and in high concentrations, it may be linked to the formation of potentially toxic or carcinogenic compounds. Slow drying limits its formation, thus contributing to the quality and safety of the pasta.

The Fabbri method

In our pasta factory, slow drying is not a trend but a tradition consolidated over 5 generations. We still use our historic Garbuio drying cell from 1956, alongside modern chambers modified by Giovanni Fabbri that follow the same principle: temperatures below 38 °C and drying times ranging from 3 to 6 days (72 to 144 hours), depending on the pasta shape.

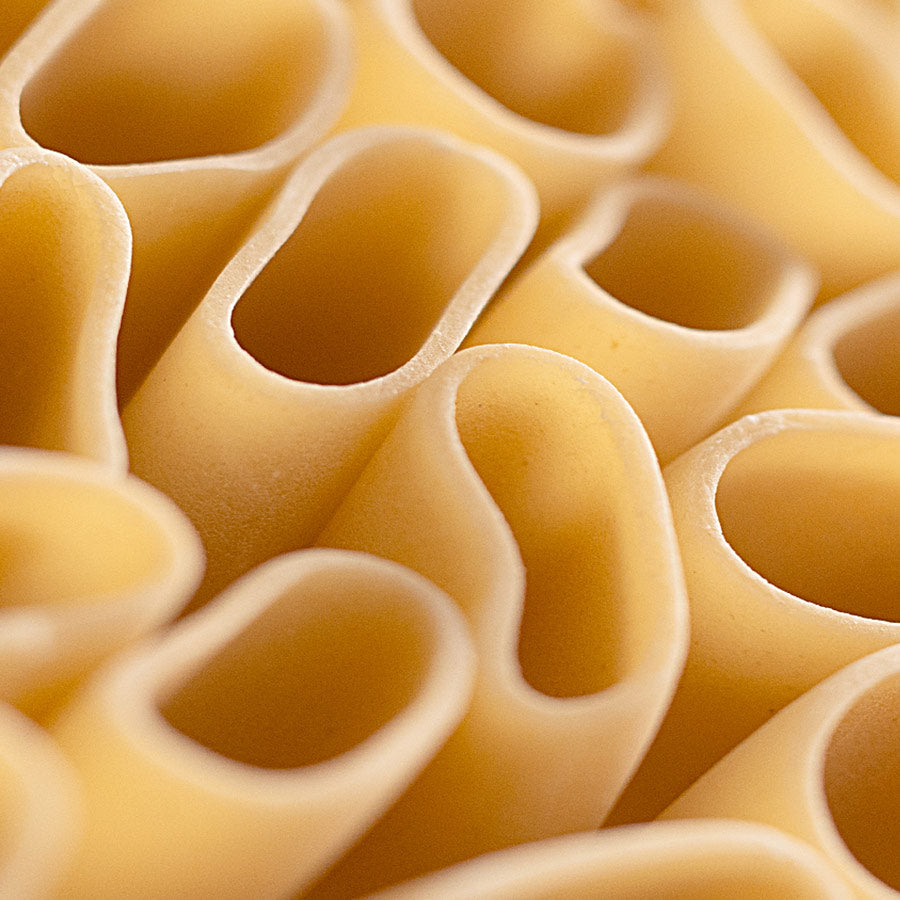

This choice allows us to produce pasta with an elastic, porous texture, excellent cooking resistance, and a flavor that truly reflects the grain.

To dry slowly means to respect the wheat, the work, and those who will bring the pasta to the table. It means choosing quality, even when it takes more time. And it is precisely time, together with care, that makes the difference on the plate.